Intro

Automation tool & die is the phrase you type when you want to make die-making faster, safer, and more predictable. Are you researching how automation can transform a tool and die shop, or looking for the best systems to add CNC, robotics, and data-driven maintenance? Your intent is mostly informational with a practical, transactional edge, you want clear steps, vendor patterns, and examples you can use in a shop floor pilot.

In my experience working with small and medium toolrooms, the biggest wins come from automating repetitive set-ups, integrating CNC programs with job data, and adding simple sensing to prevent tool failures. This post explains what automation for tool and die shops means, why it matters for quality and throughput, how to start a pilot, code and integration examples, recommended tools, and the legal and safety checks every shop should run before deploying automated systems. Key claims are backed by industry sources so you can follow up and validate choices. SME+1

What automation tool & die means, and why it matters

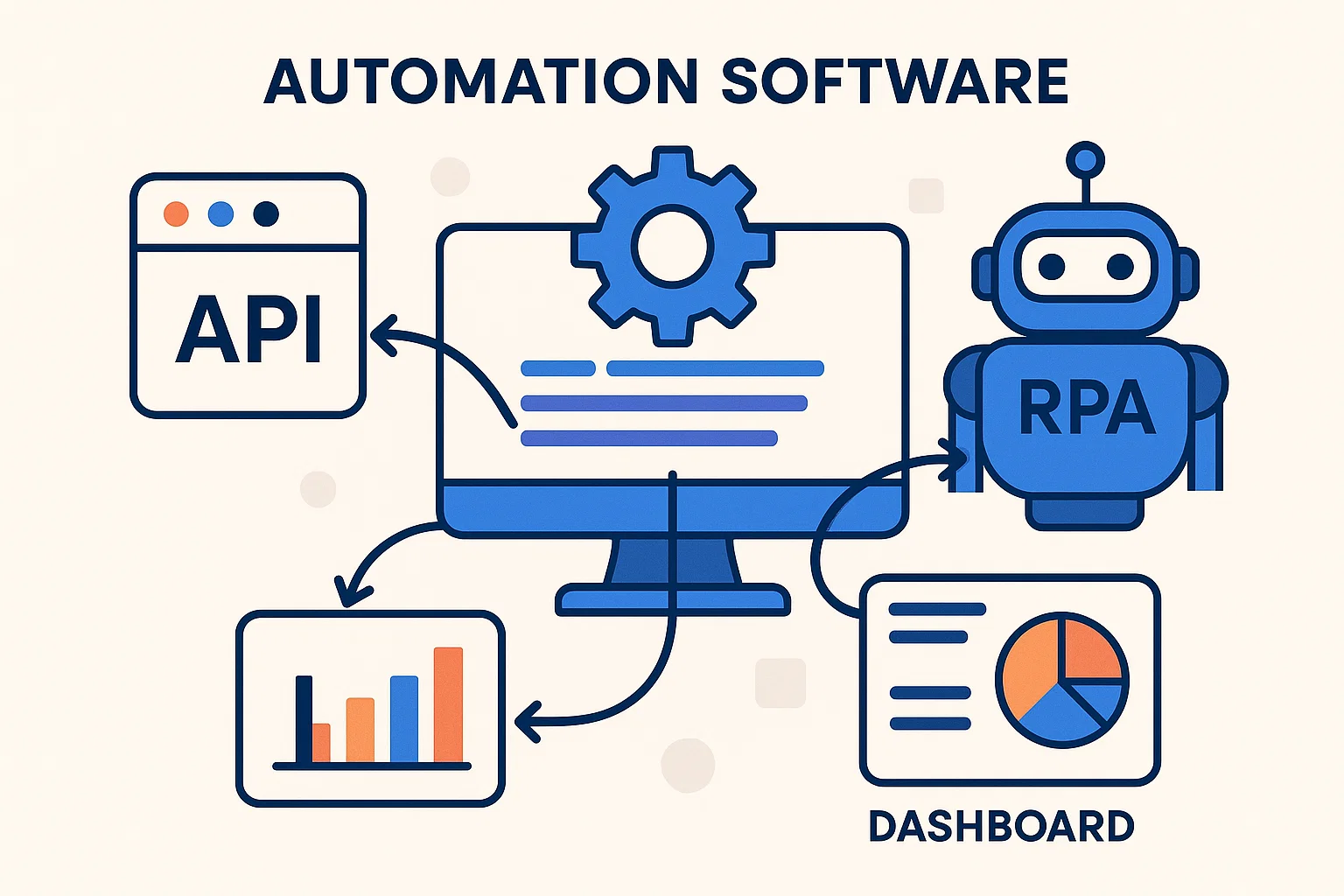

Automation in the tool and die world combines machine tools, robotics, software, and sensing to streamline making dies, molds, and stamping tools. When I say automation tool & die, I include automated CAM-to-machine handoffs, robotic part handling, automated tool changers, in-process measurement and condition monitoring. These elements reduce setup time, improve repeatability, and let skilled makers focus on high-value tasks. SME+1

A short history and context

Tool and die shops have always been early adopters of accuracy tools, from jig grinders to EDM. The current wave of automation is driven by Industry 4.0 concepts, meaning networked machines, data collection, and predictive maintenance. Shops that adopt automation see fewer scrap parts and more consistent tolerances, because processes become repeatable and instrumented. ResearchGate+1

Where automation makes the biggest difference

- CNC programming and transfer, automatic posting from CAM to machine reduces translation errors. automationtd.com

- Robotic loading/unloading, which supports lights-out machining for long runs. standardbots.com

- Automated tool change and presetting, cutting manual setup time dramatically. Lazersafe

“Process consistency is the prerequisite for automation success in toolrooms,” industry experts note, pointing to the need for accurate machine tools and reliable tooling systems. SME

How to start automating a tool and die shop, step-by-step

This section gives a practical, numbered plan you can follow to pilot automation tool & die capabilities in a real shop.

- Map your process

- List every manual step from CAD handoff to finished die, mark bottlenecks and repetitive tasks. Focus on high-frequency pain points first.

- Choose low-risk automation wins

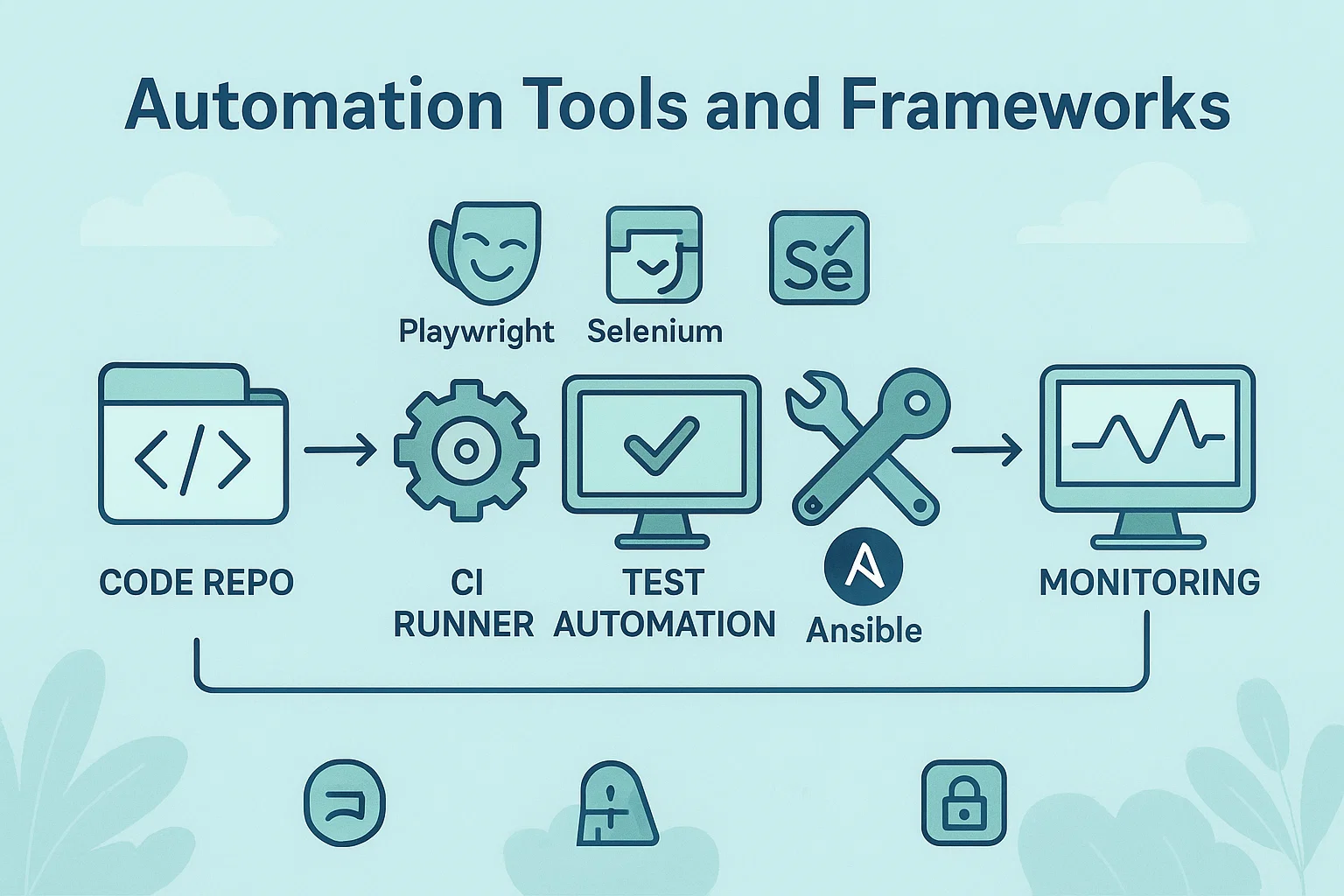

- Pick one process to automate, for example CAM post-processing automation or automatic tool measurement. These deliver value quickly with limited integration. automationtd.com

- Select hardware and software

- Use reliable CNCs, ATCs, and cobot arms from reputable vendors, and choose CAM software that has robust post-processors for your controllers. Vendors often provide integration guides. SME+1

- Implement data capture and logging

- Add simple sensors and a shop-floor data store, even a lightweight SQL database, to log cycle times, tool life, and alarms. Data lets you iterate. ResearchGate

- Build a safe test environment

- Run the new workflow in a test cell, simulate failures, and validate that interlocks and E-stops behave as expected.

- Train staff and document

- Teach operators and toolmakers the new workflow, and keep a one-page procedure at the machine for quick reference.

- Scale incrementally

- Once stable, expand automation to the next process and reuse lessons learned.

Quick automation script, CAM job deployer (Node.js)

// Simple Node.js uploader to push a CAM G-code file to a CNC server API

// For demo only, add auth and robust error handling in production

const fs = require('fs').promises;

const fetch = require('node-fetch');

async function uploadGcode(filePath, apiUrl, token) {

try {

const code = await fs.readFile(filePath, 'utf8');

const resp = await fetch(apiUrl + '/jobs', {

method: 'POST',

headers: {'Authorization': `Bearer ${token}`, 'Content-Type': 'text/plain'},

body: code

});

if (!resp.ok) throw new Error('Upload failed ' + resp.status);

const data = await resp.json();

console.log('Job queued', data.jobId);

return data;

} catch (err) {

console.error('Upload error', err);

throw err;

}

}

// usage: uploadGcode('part.nc','https://cnc.local/api','MYTOKEN');

This example automates the handoff step between CAM and machine, reducing transcription errors.

Python example, simple OPC UA monitor for tool life

# python opcua monitor snippet, logs spindle hours and contact sensor state

from opcua import Client

import time

client = Client("opc.tcp://machine.local:4840")

try:

client.connect()

node_spindle = client.get_node("ns=2;i=3001") # example node

node_tool = client.get_node("ns=2;i=3002")

while True:

spindle_hours = node_spindle.get_value()

tool_state = node_tool.get_value()

print("Spindle hours:", spindle_hours, "Tool state:", tool_state)

# add DB write here

time.sleep(60)

except Exception as e:

print("Monitor error", e)

finally:

client.disconnect()

Use OPC UA or vendor APIs to collect machine telemetry for predictive maintenance.

Best practices, recommended tools, pros and cons

Best practices

- Start small, automate a single repeatable task, then iterate.

- Prioritize accuracy and consistency, not just speed. Automation shines when process outputs are predictable. SME

- Instrument for data, collect enough telemetry to diagnose issues later. ResearchGate

Recommended toolchain

- CAD/CAM: industry-standard CAM with direct post-processors. automationtd.com

- CNC controls: choose machines with open communications or OPC UA support. SME

- Automation hardware: cobots for part handling, ATC systems for tool changes. Lazersafe+1

Pros

- Higher uptime and repeatability, reduced scrap, ability to run lights-out. SME+1

Cons

- Upfront cost, integration complexity, and the need for disciplined data management. Not every job benefits equally from automation.

“Digital transformation unlocks value when paired with process discipline,” analysts say, noting that technology alone is not a silver bullet. McKinsey & Company

Challenges, legal and ethical considerations, and troubleshooting

Safety and compliance

Automating machine functions introduces safety risks, from unexpected tool movements to robotic collisions. Use industry safety standards, implement hard E-stops, interlocks, and validated safety-rated controllers. Train staff rigorously and document procedures.

Data and IP risks

Protect CAM files and tooling data, control access to job files, and encrypt backups. If you share files with contract partners, use contracts and access controls. Industrial espionage and IP leakage are real concerns.

Regulatory and legal notes

If your automation involves networked systems or cloud storage, ensure compliance with applicable data protection laws and export controls. This content is informational, not legal advice, consult counsel for jurisdiction-specific requirements.

Troubleshooting tips

- Intermittent errors: check communication retries and network stability, implement exponential backoff.

- Tool breakage: verify tool preset accuracy and add spindle load monitoring for early detection.

- Unexpected part dimensions: add in-process probing and update CAM offsets dynamically.

Ethical design

Automate to amplify human skill, not to displace critical knowledge. Use automation to reduce repetitive strain and hazardous manual tasks, and keep technicians involved in oversight.

Conclusion and call to action

automation tool & die is a practical path to better quality, faster turnarounds, and safer shops when implemented carefully. Start with a clear map of your processes, pick one repeatable task to automate, instrument for data, and scale incrementally. Remember, automation multiplies both strengths and weaknesses, so pair technology with strong procedures, training, and safety controls.

If you want, I can help draft a one-page automation pilot plan for your shop, or convert the Node.js and Python snippets into deployable scripts. Tell me which process you want to automate first, and I will sketch the pilot.

FAQs

What is automation tool & die?

automation tool & die refers to applying automation technologies like CNC integration, robotics, and data systems to toolmaking, die-making, and stamping workflows, to improve repeatability, safety, and throughput.

How do I start automating a small toolroom?

Map your workflows, pick a single repetitive task to automate, choose compatible CAM and CNC hardware, add basic sensors, run a test cell, and document the process for staff training.

Which software is best for tool and die automation?

Use mature CAM systems with robust post-processors, combined with a machine communications layer that supports OPC UA or vendor APIs for telemetry and job transfer. automationtd.com+1

Can I run machines lights-out in a tool and die shop?

Yes, with robotic loading, reliable fixturing, tool monitoring, and process consistency you can run lights-out for suitable jobs, but safety and monitoring are critical. standardbots.com

What are common pitfalls in automation projects?

Skipping process mapping, under-investing in training, and ignoring data collection. These lead to fragile systems that fail under variation. McKinsey & Company

Do I need special networking for machine telemetry?

A reliable local network and a secure method for machine communication, often OPC UA or vendor protocols, are essential for stable telemetry and remote monitoring. ResearchGate

How do I protect my CAM and die designs?

Restrict access, use secure file transfer, maintain version control, and use contracts and NDAs with partners to limit IP exposure.

Is automation expensive for small shops?

Initial cost can be significant, but prioritizing high-frequency tasks and using modular automation can shorten payback times and increase competitiveness. SME